Fluid Bed Dust Bag

Send Inquiry

Product Role

1. Drug powder should be filtered by Fluid Bed Dust Bags to prevent it from dispersing into the exhaust system.

2. The Fluid Bed Dust Bags used should have low resistance and high efficiency to ensure a good bed pressure drop. This will help achieve a good ventilation heat exchange rate, improve drying efficiency, and reduce energy consumption.

3. The granulation effect is affected by the uniformity of the pore size of the Fluid Bed Dust Bags (3μm, 5μm, 10μm). The higher the uniformity, the better the internal quality uniformity of the particles. After granulation of micronized raw materials, the uneven pore size of the Fluid Bed Dust Bags can result in decreased or uneven content.

4. The antistatic ability and welding seam technology of the Fluid Bed Dust Bags directly affect the anti-adhesion force, which in turn affects the product yield. For example, in the FBD200 fluidized bed, a general Fluid Bed Dust Bags causes each batch of powder to agglomerate and adhere, resulting in a loss of about 1.5-2.0kg. Based on the production calculation of 2 batches per day and 180 days (life of the Fluid Bed Dust Bags ), the material loss can be up to 360kg. Choosing high-quality Fluid Bed Dust Bags can effectively reduce losses, energy consumption, and costs, while increasing yields. Therefore, the Fluid Bed Dust Bags is an excellent choice, and we look forward to working with you to improve the level of fluidized bed drying and granulation technology.

Main Parameter

| project | numerical value | unit |

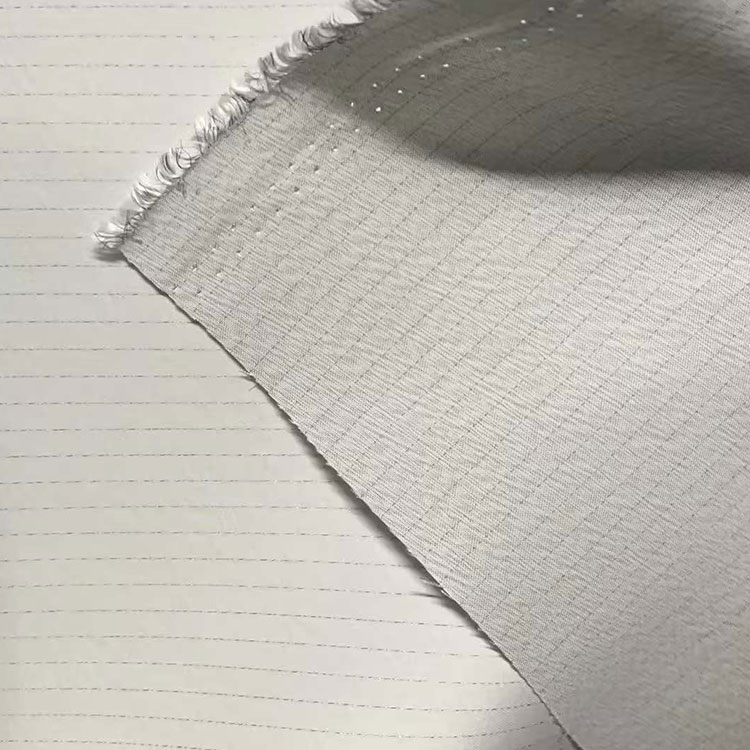

| Material | POLYESTER | |

| Weight | 180-200 | g/㎡ |

| thickness | 0.26-0.28 | mm |

| Breathability | 80-120 | mm/s |

| conductive thread | Knitted black silk (striped style) | |

| Conductive wire spacing | 5.0 | mm |

| surface resistance | 10/6/9/6/3/6/0 | Ω |

| organizational structure | Sparse weave (100×300D)/filament | |

| Longitudinal breaking strength | ≥1000 | N/5cm |

| Transverse breaking strength | ≥1300 | N/5cm |

| Operating temperature | <130 | ℃ |

| Chemical compatibility | Resistant to weak acids, weak bases, solvents, and active oxidants | |

| surface form | Glossy | |

| Precautions | Moisture-proof, avoid strong light exposure | |

The table is for reference only, we support OEM, ODM.