PET Antistatic Filter Bag

Send Inquiry

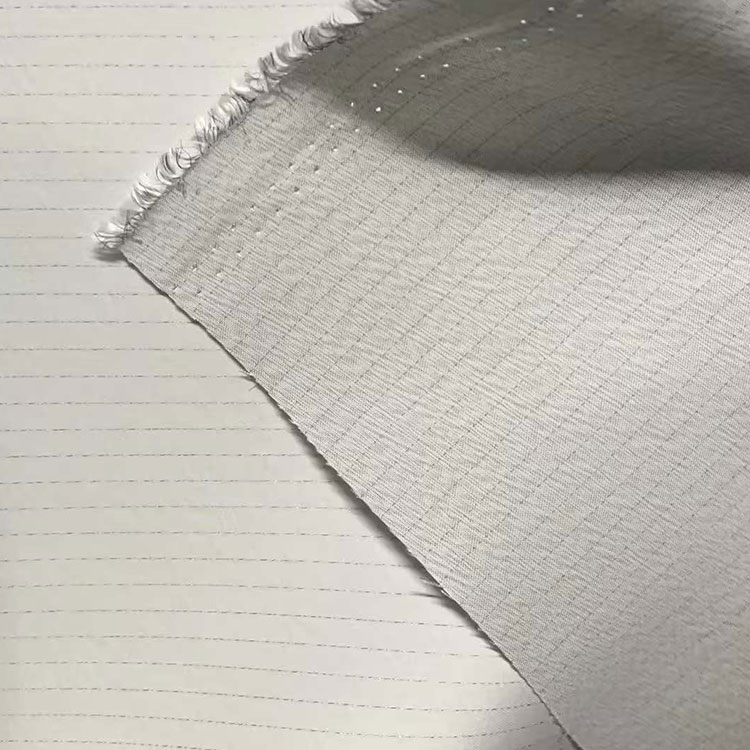

PET antistatic filter bag is a common explosion-proof dust removal filter material that is economical and affordable by adding conductive yarn to polyester during the textile process to achieve antistatic function.

In order to achieve the antistatic function, conductive fiber or stainless steel fiber can be added to the PET yarn. Antistatic filter material can be used in static electricity, explosion and flammable dust environments to make PET antistatic filter bags. This is important to prevent industrial dust from exploding at a certain concentration. Antistatic filter bags release the charge brought by dust-containing gases during use, which can prevent the discharge of charge from forming sparks and causing explosions.

Product Specification

| Polyester/anti-static base fabric | Polyester/conductive fibre/filament base fabrics | Polyester/stainless steel fibre/filament base cloth | |||

| Gram Weight(g/m2) | 500 | 500 | 500 | ||

| Thickness(mm) | 1.6 | 1.8 | 1.8 | ||

| Air Permeability(m3/m2/min) | 12 | 12 | 12 | ||

| Tensile Strangth(N/5×20cm) | Warp | >800 | >1000 | >1000 | |

| Weft | >1300 | >1300 | >1300 | ||

| Elongation(%) | Warp | <25 | <35 | <35 | |

| Weft | <55 | <55 | <55 | ||

| Continuous Operating Temperature(℃) | ≤130 | ≤130 | ≤130 | ||

| Instantaneous working temperature(℃) | 150 | 150 | 150 | ||

| Acid Resistance | Excellent | Excellent | Excellent | ||

| Alkali Resistance | Good | Good | Good | ||

| Wear Resistance | Excellent | Excellent | Excellent | ||

| Hydrolytic stability | Good | Good | Good | ||

| Post-processing method | Burnishing and calendering/heat setting/Teflon/coating | Burnishing and calendering/heat setting/Teflon/coating | Burnishing and calendering/heat setting/Teflon/coating | ||

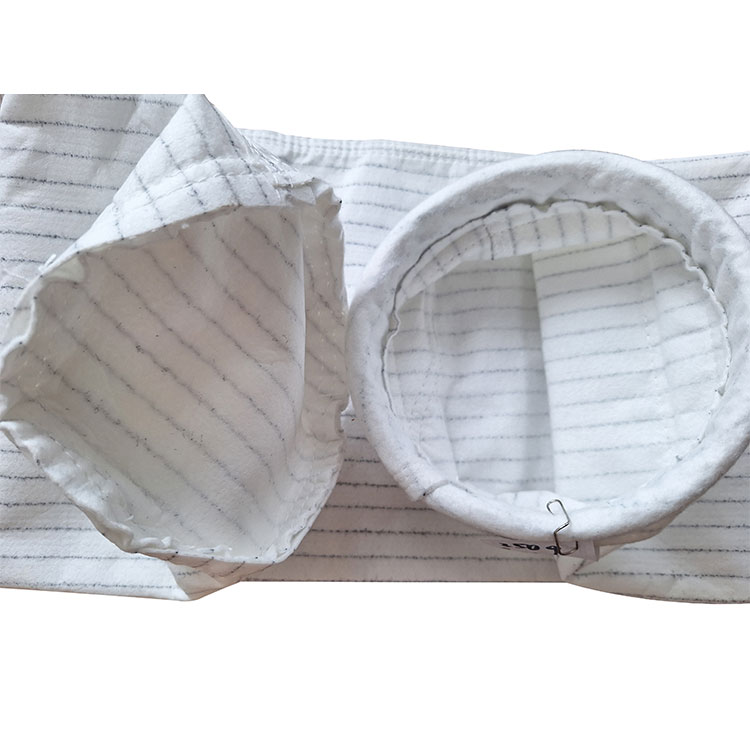

Size:

There is no uniformly specified size standard for dust bag, and its size is determined according to the bag filter, the size of the flower plate hole and the length of the bag body.

Commonly used specifications are:

Calibre: ø120mm, ø125mm, ø130mm, ø150mm, ø160mm, ø180mm.

Bag length: 1m - 10m

Product Application

1. Chemical industry: in the chemical production process, powder, granular materials in the transmission and processing process is prone to static electricity, PET antistatic filter bag can effectively prevent dust adsorbed on the filter bag due to static electricity, reduce the difficulty of dust removal, improve the stability of equipment operation.

2. Metal smelting industry: metal smelting process produces dust not only high temperature, fine particles, but also with conductive dust, the use of PET antistatic filter bag can effectively avoid dust due to electrostatic agglomeration triggered by the safety risks.

3. Pharmaceutical and food processing industries: these industries for the handling of dust requirements are extremely high, anti-static dust bag can prevent dust because of electrostatic adsorption in the equipment, to ensure product quality and safety and cleanliness of the production environment.

4. Electric power, cement, ceramics and other industries: in these industries, there are also a large number of dust processing needs, the use of PET antistatic filter bag can improve the dust removal effect, reduce the cost of equipment maintenance, to meet the requirements of environmental emissions.