Industrial Diaphragm Replacement Kit for Pulse Jet Valve

Send Inquiry

Qingdao Star Machine's Industrial Diaphragm Replacement Kit for Pulse Jet Valve features high-quality, reinforced diaphragms made from Buna (NBR), a durable material that ensures a long operating life, even in challenging environments. The cover is crafted from stainless steel 304 (SS304), providing added strength and resistance to corrosion.

Our Diaphragm Replacement Kit for 1.5 inch Pulse Jet Valve is compatible with the following pulse valves: SCG353A047, G353A065, G353A046, and G353A045. The repair kit comes with a rubber diaphragm assembly/seat assembly, core assembly and two springs for convenient repair. They are designed to withstand working pressures ranging from 0.05 to 1.0 Mpa and temperatures between -20°C and +82°C. What's more, these diaphragms have been tested to ensure a remarkable lifespan of 1 million cycles, giving you peace of mind knowing that your equipment will run smoothly and efficiently for years to come.

Each Diaphragm Replacement Kit for 1.5 inch Pulse Jet Valve comes complete with everything needed for a successful repair, including detailed instructions and expert technical support. Our team of professionals is dedicated to providing exceptional customer service, ensuring that you receive the assistance you need when you need it.

Industrial diaphragm replacement Kit for Pulse Jet Valve are used in a wide variety of industries:

Dust Collection: In dust collectors, pulse jet valves are used to clean filters by discharging compressed air. The diaphragms in these valves ensure that the air is discharged at the correct pressure and time.

Air Compression: In air compression systems, pulse jet valves are used to control the flow of compressed air to various parts of the system. The diaphragms help maintain the pressure and flow rate required for efficient operation.

Automation: In automation systems, pulse jet valves are often used to control pneumatic actuators and other equipment. The diaphragms ensure that these devices operate reliably and accurately.

Reminder:

* The Valves and diaphragms should be inspected annually

*When maintaining the system and installing valves, it is important to ensure that the power and pressure are disconnected.

Key Selling Points

Premium Diaphragm Material:

The diaphragms in this kit are made from specially formulated rubber, which offers unmatched durability and resilience to withstand the rigors of industrial environments.

Precision Fit and Seal:

Each diaphragm is precision molded to ensure a perfect fit with the pulse jet valve, eliminating the risk of leaks and ensuring optimal performance.

Easy Installation:

The kit includes comprehensive installation instructions and necessary tools, simplifying the replacement process for both experienced professionals and novices.

Cost-Effective Solution:

By replacing the diaphragm instead of the entire valve, businesses can realize significant cost savings, thereby improving overall operational efficiency.

Compatibility and Versatility:

Customers operate different industrial settings. The Industrial Diaphragm Replacement Kit is designed to fit a variety of pulse jet valve models, ensuring versatility in different applications.

Performance Reliability:

Customers prioritize the reliability of their industrial systems. Industrial diaphragm replacement kits ensure that pulse jet valves continue to operate at peak efficiency, preserving the integrity of your dust collection process.

Environmental Impact:

Sustainability is a growing concern for industrial operations. By replacing diaphragms to extend the life of your pulse jet valves, this kit helps reduce waste and your environmental footprint.

Durability and Lifespan:

Industrial environments can be very demanding on equipment. The high-quality diaphragms in this kit are designed to withstand these conditions, ensuring continued performance over the long term.

Product Parameter (Specification)

| Material: | Nitrile Or Viton | Port Size: | 1-1/2″ |

| Fitted Valve Code: | SCG353A047 | Working Temperature: | -20℃-80℃ |

| Working Pressure: | 0.05-1.0 Mpa | ||

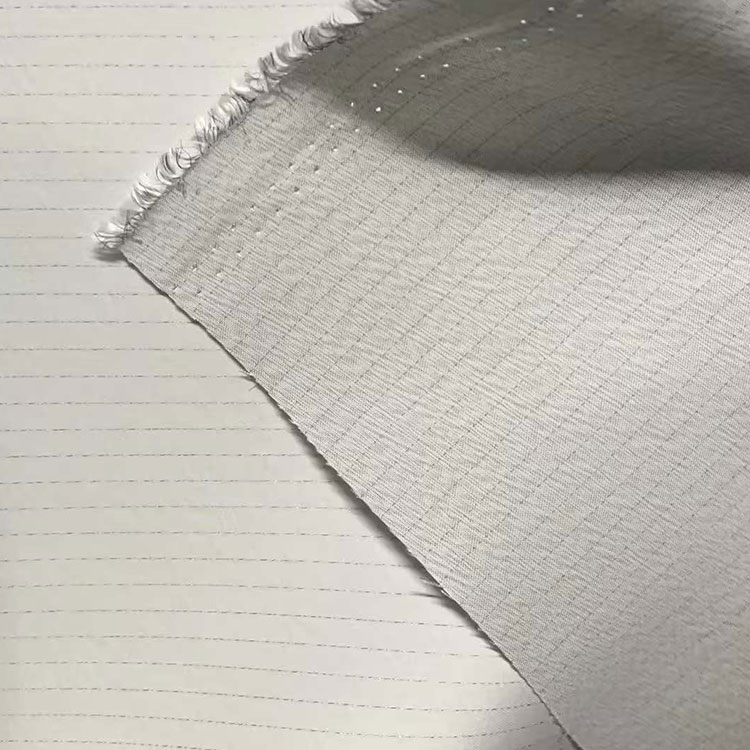

Product Detail Photo

Our Diaphragm Replacement Kit for 1.5 inch Pulse Jet Valve will be packaged in ziplock bags, or if you order in bulk, we can provide additional packaging at your request.

FAQ

Q: How resistant are the diaphragms to industrial wear and tear?

A: Designed with durability in mind, it can withstand repeated cycles of pressure and temperature changes, maintaining its structural integrity.

Q: Is this kit compatible with my existing pulse jet valves?

A: Designed for universal compatibility, it can be customized to fit the most common valve models, making it a versatile solution for a variety of industrial needs.

Q: How does this kit support sustainability efforts?

A: By minimizing the need for new valve replacements, it reduces the carbon footprint associated with manufacturing and disposal, meeting our customers’ sustainability goals.

Q: How do the materials ensure longevity?

A: The rubber compound is designed to withstand high pressures, temperature fluctuations and corrosive agents, extending the life of the valve.

Q: How does this kit help save costs?

A: It eliminates the need for expensive valve replacements, reducing maintenance expenses and maximizing return on investment.