Industrial Filter Cloth

Send Inquiry

The industrial filter cloth produced by Qingdao Star Machine can be customized. If necessary, we can provide samples free of charge.

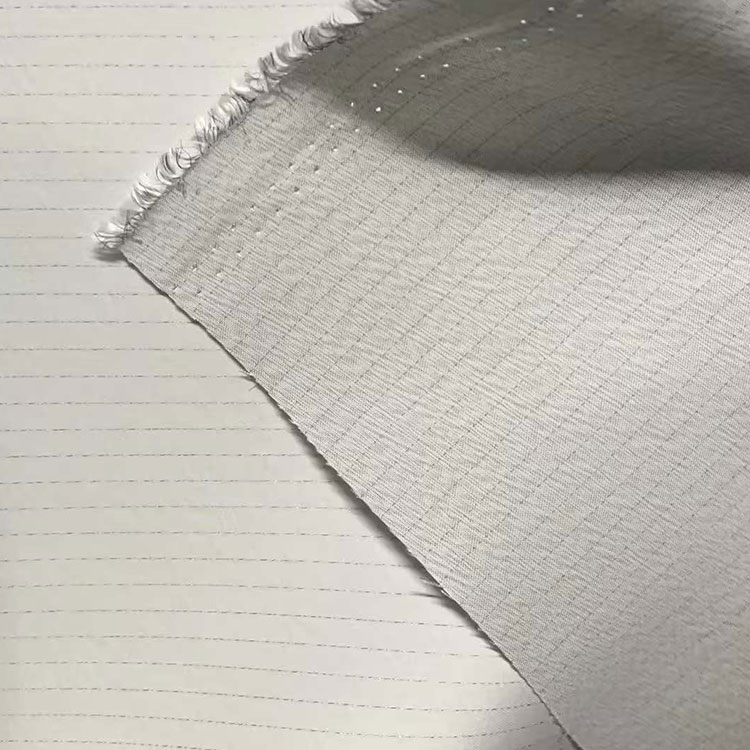

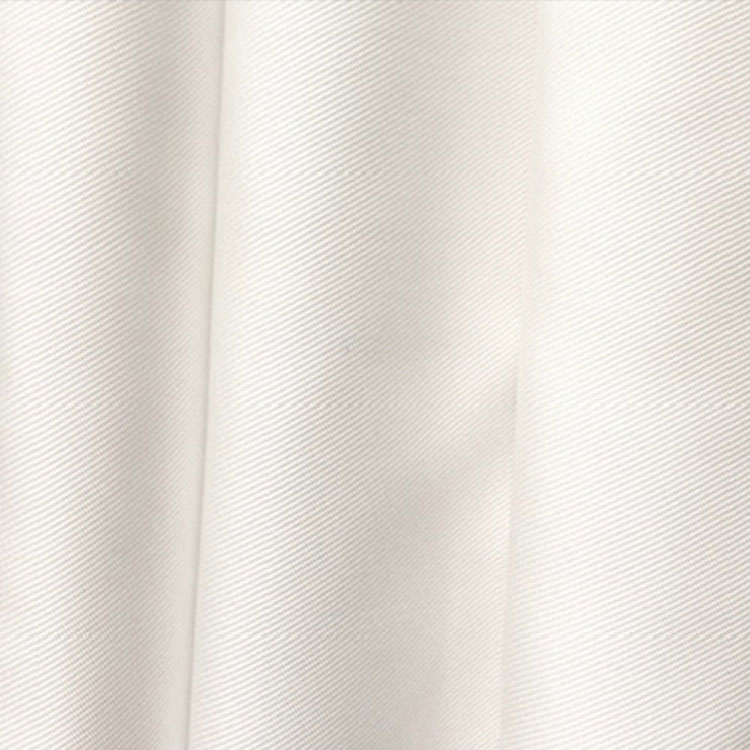

Our industrial filter cloths include belt filters, plate and frame filters, chamber filters and centrifuges, made of PP, PE, nylon, vinylon, etc., in both woven and needle felt forms. Industrial filter cloth is used in loads of industries like petroleum, chemicals, smelting, dyes, pharmaceuticals, food and more. It's used for separating liquids and solids, and the filtration is really precise (0.25-150 micron).

Product Parameter (Specification)

| Model | Weaving | WEIGHT | Density (PC/10CM) | THICKNESS | Breaking Strength (N/5*20CM) | Elongation At Break (%) | Air Permeability | |||

| G/M² | Warp | Weft | MM | Warp | Weft | Warp | Weft | (L/M².S) | ||

| 621 | Polyester Long Fiber | 340 | 192 | 130 | 0. 65 | 4380 | 3575 | 50 | 30 | 55 |

| 621B | Polyester Long Fiber | 440 | 260 | 145 | 0. 78 | 4380 | 3575 | 50 | 30 | 60 |

| 120-14 (747) | Polyester Staple Fiber | 248 | 226 | 158 | 0. 75 | 2244 | 1371 | 31 | 15 | 120 |

| 120-15 (758) | Polyester Staple Fiber | 330 | 194 | 134 | 0. 73 | 2721 | 2408 | 44.2 | 21.3 | 100 |

| 120-16 (3927) | Polyester Staple Fiber | 524 | 156 | 106 | 0. 90 | 3227 | 2544 | 60 | 23 | 25 |

| Polyester Needle Punched | 1.80 | 18 | ||||||||

How to measure the industrial filter cloth

To know the accurate size of the industrial filter cloth,we need to measure the thickness of the machine filter plate, the length and width of the filter plate, and the diameter of the center hole of the filter plate.

Product Features and Applications:

1. PP long fiber industrial filter cloth has good wear resistance, high strength, good air permeability, fast water filtration and easy cleaning.

2. PE long fiber industrial filter cloth has a smooth surface and good air permeability, suitable for powder filtration. 858 polypropylene polyester blended filter cloth is suitable for chemical and pharmaceutical companies, but not for powder filtration. 4212 polypropylene short fiber industrial filter cloth is a filter material specially developed for dye factories.

3. Vinylon industrial filter cloth has poor elasticity, but good wear resistance, can withstand strong alkali erosion, good hygroscopicity, and is easy to combine with rubber, and is widely used in the rubber industry. The disadvantage is that it is not resistant to high temperatures, the filter cloth will shrink at 100°, and has poor acid resistance.

Production Process