Solid liquid Separation Filter Press Cloth

Send Inquiry

Qingdao Star Machine is a Solid-liquid Separation Filter Press Cloth suppliers, this filter cloth filter media made of natural fibers or man-made fibers. Commonly used materials include cotton,glass fiber, aramid, chinylon, polyester and other synthetic fibers.

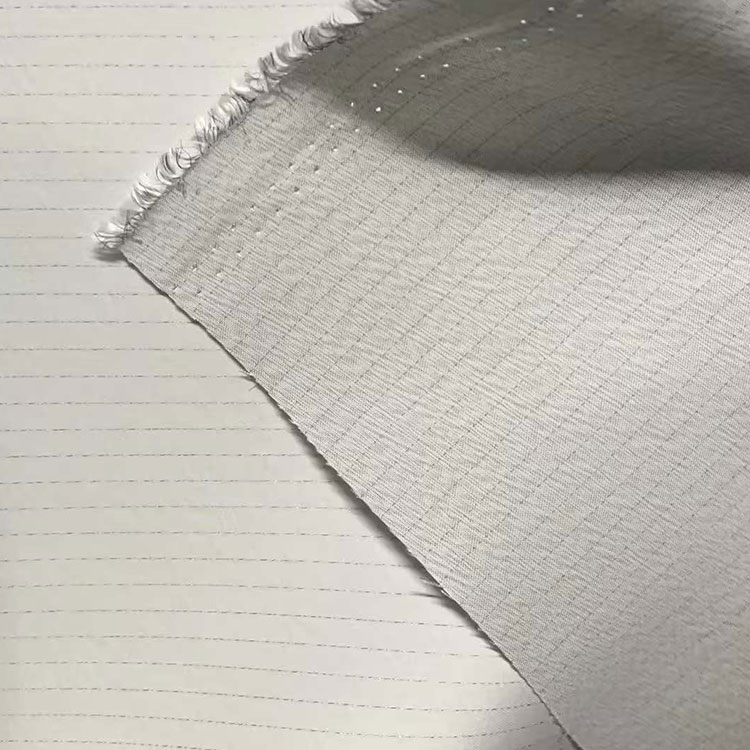

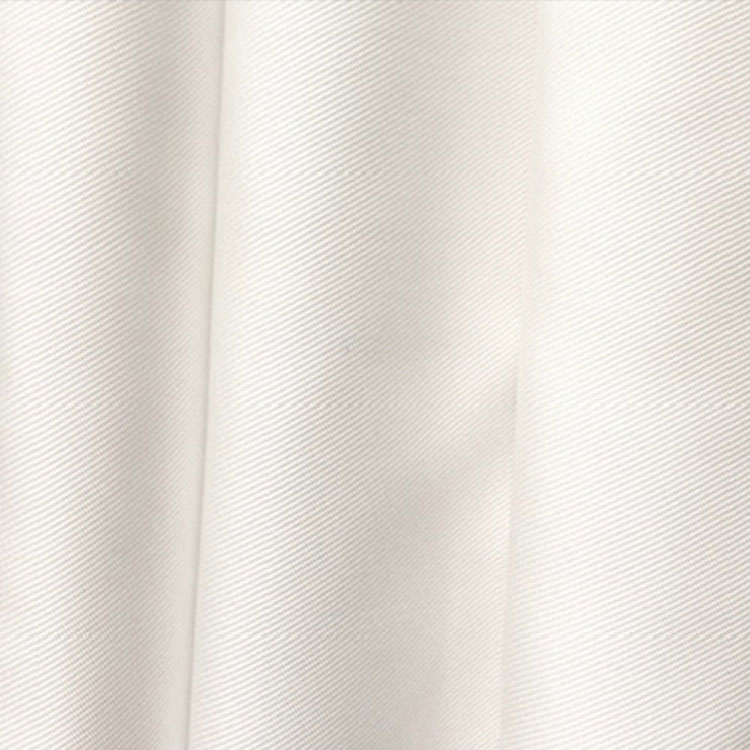

Our Solid-liquid Separation Filter Press Cloth is durable and sturdy due to adopting plain weave, twill weave or non-woven fabric needle punched forming, increasing its service life.

Our filter cloth has excellent filtration performance, high precision and resistance to acid, alkali, and high temperatures, in compliance with strict environmental standards. Free samples available upon request.

Product Feature And Application

Filter presses are mainly divided into two types: plate and frame filter presses and box filter presses. Solid-liquid Separation Filter Press Cloth are primarily used in filter press applications. These filter cloths can be further categorized into plate and frame refining solid-liquid separation and catalyst recovery filter cloths, as well as box refining Solid-liquid Separation Filter Press Cloth.

Box type filter cloth: The entire Solid-liquid Separation Filter Press Cloth is cut into 2 pieces and processed to form a set, that is, 2 pieces form a set. The position of the feeding port has intermediate feeding and upper feeding. It is divided into open flow type, undercurrent type, washable type, and non washable type. Its processing technology is consistent with the box filter press.

Plate and Frame Filter Cloth: A complete filter cloth is used for punching according to the direction of the feeding port designed by the machine. It is a large filter cloth that does not need to be cut.

The main materials of polypropylene filter cloth are 621,3927, 750A, 750B, 750AB, 747,758,108C, monofilament filter cloth, and non-woven fabrics with different GSM.

Our Solid-liquid Separation Filter Press Cloth products are widely used in solid-liquid separation supporting devices in industries such as mining, metallurgy, food, pharmaceutical, chemical, printing and dyeing, coal, building materials, sewage treatment, etc., such as box pressure filtration.

Our company produces and processes various specifications and models of filter press filter cloth, plate frame filter cloth, diaphragm filter press filter cloth, monofilament filter cloth, etc

Any specification and model can be processed with samples or drawings.

Our Solid-liquid Separation Filter Press Cloth materials can be selected based on the properties of the filtering material, including polyester filter cloth, polypropylene filter cloth, monofilament filter cloth, non-woven fabric for plate and frame, etc