Solvent Recovery Catalyst Separation and Particle Removal Filter Bag

Send Inquiry

Solvent recovery catalyst separation and particle removal Filter Bag advantage;

1. The production of high-speed industrial sewing machines without silicone oil cooling will not cause silicone oil pollution.

2. The improved seam at the bag opening does not have a high protrusion, resulting in side leakage without needle holes, resulting in side leakage.

3. All labels labeled with product specifications and models on the filter bag are easily removed to prevent contamination of the filter solution by labels and ink during use.

4. The filtration accuracy range is from 0.5 microns to 300 microns, and the materials are divided into polyester and polypropylene filter bags.

5. Argon arc welding technology for stainless steel and galvanized steel rings. The diameter error is only less than 0.5mm, and the horizontal error is less than 0.2mm. Installing the filter bag made of this steel ring in the equipment can improve the sealing degree and reduce the probability of side leakage.

Our product can be customized. If necessary, we can provide free samples.

Product Feature And Application

| Material | Structure | Grade | Sewing | Filtering |

| PO | Needled Felt | 1/5/10/25/50/75/100/200 | Seam/Welding | Deep |

| POXL | 1/5/10/25/50/100 | Seam/Welding | Deep | |

| PE | 1/5/10/25/50/75/100/200 | Seam/Welding | Deep | |

| PEXL | 1/5/10/25/50/100 | Seam/Welding | Deep | |

| NT | 1/5/10/25/50/100 | Seam | Deep | |

| PTFE | 1/5/10/25/50/100 | Seam | Deep | |

| NMO | Monofilament | 25/50/75/100-2000 | Seam | Surface |

| 100 | Melt blown | 1/5/10/25/50 | Seam/Welding | Adsorption |

| 500 | 1/5/10/25/50 | Seam/Welding | Adsorption |

1.Solvent recovery catalyst separation and particle removal Filter Bag can be freely installed in various incompatible filters, with a retention rate of up to 99% for solid particles. They have high dirt holding capacity, strong corrosion resistance, high temperature resistance, large flow rate, easy operation, strong service life, and no fiber shedding.

2.Solvent recovery catalyst separation and particle removal Filter Bag rim can be made of galvanized or polypropylene PP plastic, with good acid and alkali resistance and toughness. Stainless steel ring products are suitable for special working environments, resistant to acid, alkali, and high temperatures.

3.Solvent recovery catalyst separation and particle removal Filter Bag select high-quality PP/PE material, acid and alkali resistant, solvent resistant, and high-temperature resistant. Use precision testing machines to ensure that the product's precision meets the standard requirements.

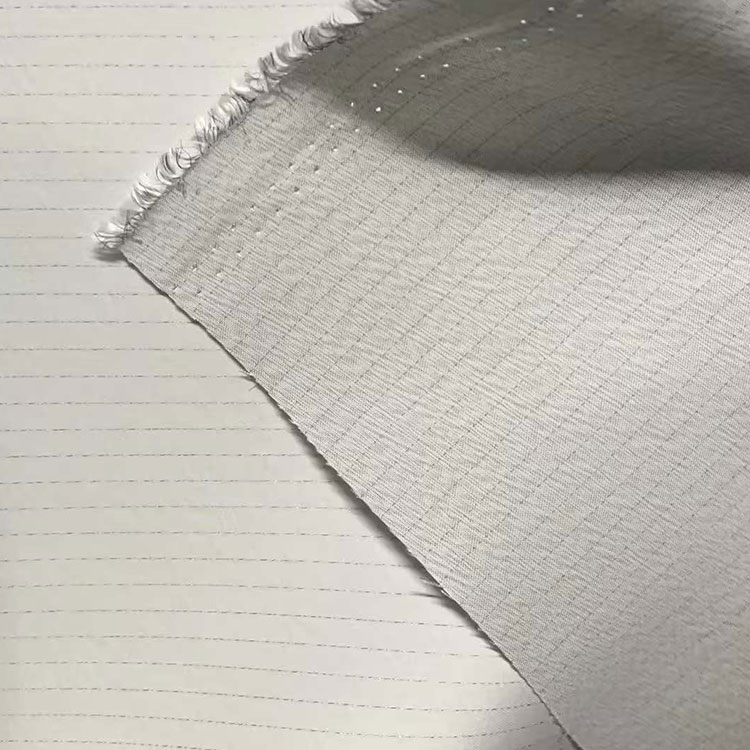

4.Solvent recovery catalyst separation and particle removal Filter Bag uses a high-speed industrial sewing machine without silicone oil cooling for five thread sewing production. The bag opening is tightly stitched without any gaps, and the stitching on the needle opening is uniform. The appearance is beautiful and the curvature is not deformed.

5.Solvent recovery catalyst separation and particle removal Filter Bag use digital in-place multi-point welding equipment to ensure that each point of welding remains firm and consistent. After special singeing treatment, it effectively prevents fiber detachment from polluting the filtrate and preventing blockage. Adopting new processes to prevent excessive clogging of filter holes to improve the service life of filter bags.