Starmachinechina 105 Pulse Jet Valve

Send Inquiry

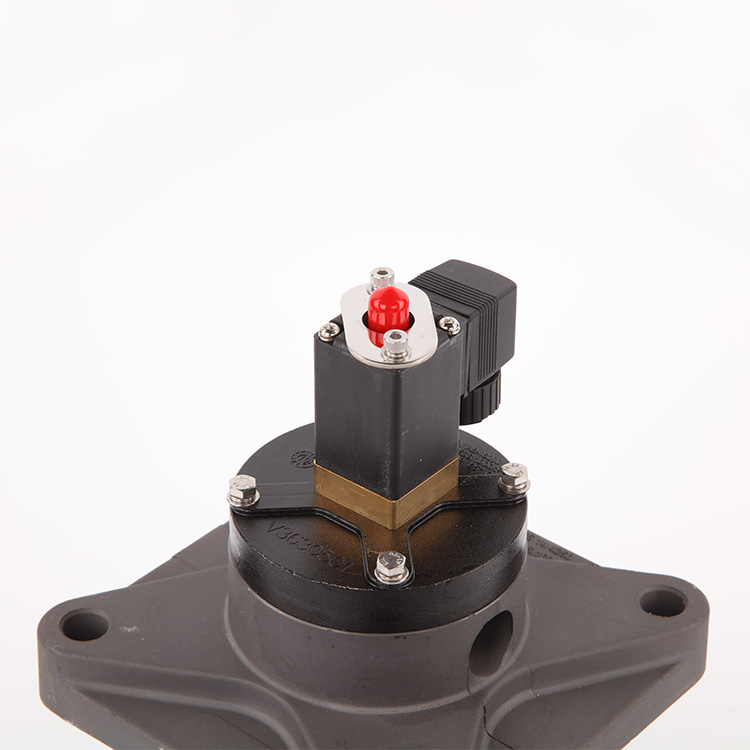

Starmachinechina 105 Pulse Jet Valve

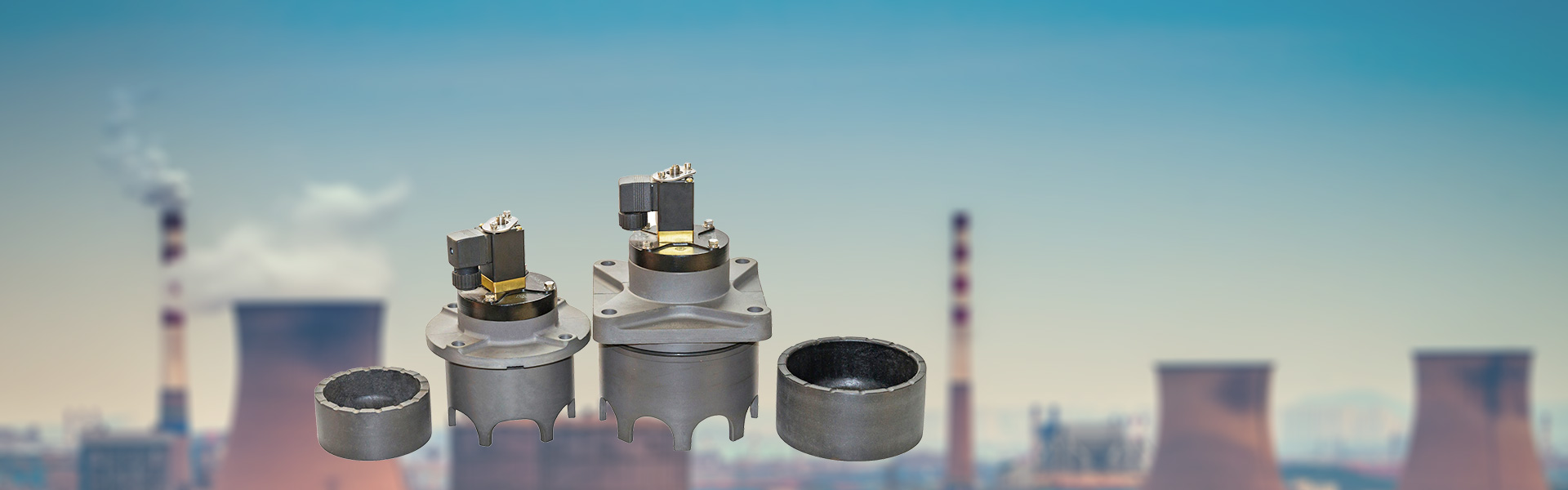

Qingdao Star Machine Starmachinechina 105 Pulse Jet Valve Fabric Filter is suited for most applications with competitive price, requiring a large filtering capacity , such a coal-fired boilers for power plants and waste-to-energy plants. Starmachinechina 105 are indirect operated solenoid valves especially designed for dust collector systems. When the solenoid is energized, trapped air above a diaphragm is quickly exhausted causing a high pressure difference across the diaphragm. Thereby the diaphragm is suddenly opened. When the solenoid is de-energized, air escapes through a hole to the chamber above the diaphragm which balances the pressure and instantly closes the valve.

Product Parameter (Specification)

| Technical Data | |

| Model | Starmachinechina 105 |

| Valve size | 3" |

| Product Name | Piston type pulse valve |

| Design static pressure | 15 bar (1500 kPa) |

| Design temperature | 100 °C/212℉ |

| Normal operating pressure | < 6 bar |

| Normal operating pressure variation | 3 bar unlimited nos |

| Material | Aluminium |

| Normal operation temperature | 50 °C/122℉ |

| Nominal diameter | DN80 |

| Protection level | IP65 |

| Cleared area | 70m2 |

| Service life | One million time blasts or 1 year |

| Number of filter bags | 22 |

Detail

> Gas cleaning method

Raw gas enters the filter compartments via inlet ducts equipped with guide vanes that distribute the gas uniformly across the filter bags. This arrangement creates a downward gravimeter gas flow along the filter bags, precipitating the dust into the hopper below.

> Pulse Jet filter cleaning

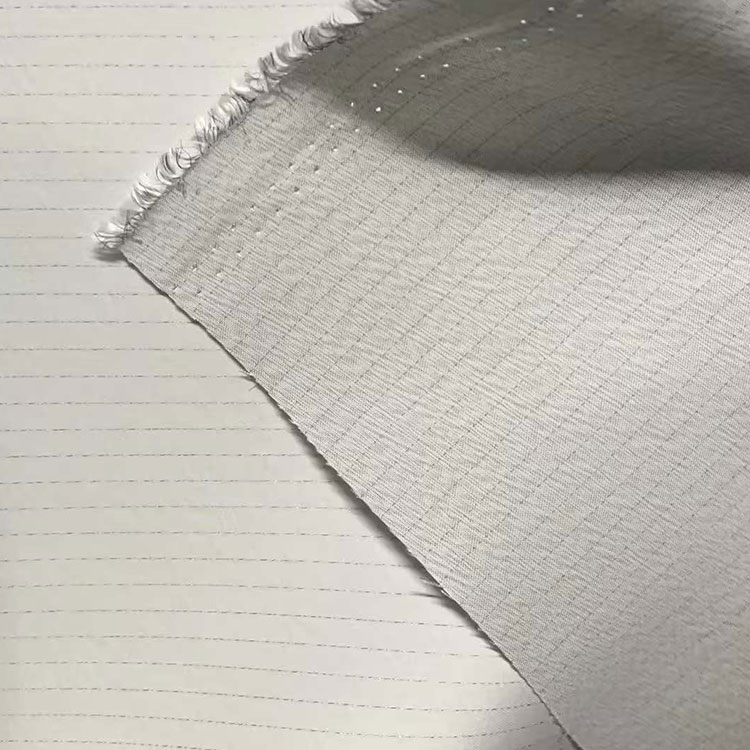

The filter bags are cleaned by means of compressed air pulses, Starmachinechina 105 Pulse Jet Valve are used here. The pulse of compressed air expands the bag, at high speed, so that dust collected on the outside of the bag is dislodged when the bag stops at its outer position. The compressed air is directed down into the bags by a tube equipped with nozzles which reduce pressure losses to a minimum and distribute the pulse pressure evenly along the row of filter bags.

> Enhanced gas absorption capacity and fine particle separation

The Starmachinechina 105 Air Pulse Jet Valve has the major advantage that further absorption of gaseous components, such as acid pollutants, take place in the dust layer formed on the bags. This layer contains reactive absorbent, resulting in enhanced absorption of acid pollutants, as well as better utilization of sorbent material.

Starmachinechina 105 pulse jet valve is specially designed for industrial dust control system, and is suitable for reverse pulse cleaning technology (Reverse Pulse Jet Cleaning). It shows excellent performance in bag filter cartridges, pleated filter elements, coated filter media, porous ceramic filter units and metal sintered fiber filter devices. It has passed ISO 16890 standard certification, with a working pressure range of 0.4-0.8MPa and a cleaning efficiency of >99.9%.

Product Details

Starmachinechina 105 Pulse Jet Valve is quick acting with high efficiency

Starmachinechina 105 has small dimensions, allows valve spacing down to 160 mm.

Pulse Valve is primarily designed to be used in combination with circular pressure tank.

Starmachinechina 105 Pulse Jet Valve is easy to install and make service

Starmachinechina 105 Solenoid Valve has a very robust design, designed for normal use at air pressure up to 600 kPa (6 bar) but static designed for 1500 kPa ( 15 bar)

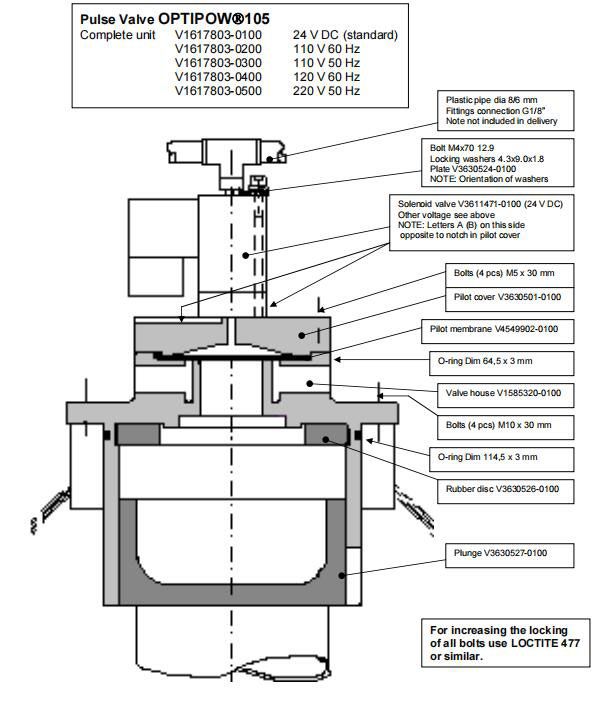

the figure 105 stands for the dimension of the plunge

Key Benefits

Compact and flexible design and the use of longer bags

Starmachinechina 105 Pulse Jet Valve is specifically designed for on-line cleaning using "Modulated Pulse Cleaning"

Unaffected by dust variations

Enhanced gas absorption capacity with fine particle separation

Low operating costs due to energy efficient pulse filter cleaning process, with low filter pressure drop and resulting in lower fan energy consumption

Easy, low-cost maintenance due to plugging of defective bags and easily accessible service area from above, requiring minimum shut down and service

After-Sales Service for Starmachinechina 105 Pulse Jet Valves

Starmachinechina 105 pulse jet valve adopts precision engineering design, and achieves ±0.01mm tolerance control through a five-axis CNC machining center, accurately meeting the engineering-level application requirements of dust removal systems. We have built a warranty service system, equipped with a professional technical team to provide 24/7 remote diagnostic support to ensure that the equipment continues to meet the operating efficiency standards.

Warranty Commitment:The standard warranty period is 12 months (from the date of delivery), and an optional extended warranty plan is provided (up to 36 months).

Service Details:The warranty covers core failure modes such as diaphragm fatigue cracking, electromagnetic coil failure, and sealing component leakage. We have established a 48-hour emergency response mechanism.