Coal Washing Filter Fabric

Send Inquiry

Product Introduction

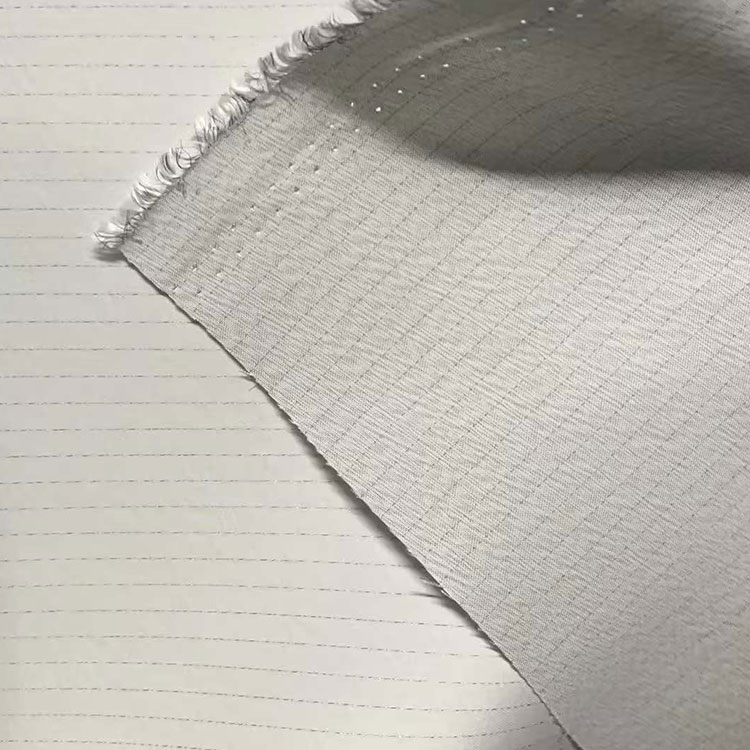

Coal washing filter fabric is a type of filter material specifically designed for the treatment and recovery of concentrated coal slime and coal washing water in coal washing and coal preparation plants. Coal washing filter fabric is usually produced by impregnation method or impregnation and rolling method. During the usage process, regular cleaning is generally required to ensure the filtration efficiency and service life. According to the characteristics and demands of the industry, Qingdao Star Machine has developed a variety of coal washing filter cloths. These filter cloths have good air permeability and water filtration performance, and are generally used in the concentration and coal preparation process of fine coal slime in coal washing and coal preparation plants. Moreover, its smooth surface area is conducive to the stripping of the filter cake, thereby reducing the difficulty of maintenance. Its structure is not prone to clogging, can be reused after cleaning, and has a long service life. It has excellent anti-scaling and anti-static properties, can improve filtration efficiency, reduce energy consumption and enhance the working environment. It is an ideal leak-stopping device for underground coal mines. The materials used in the product can be tailored to different working environments to achieve the best usage effect.

Application field:

Coal washing filter fabric is mainly applied in the following fields:

Coal slime concentration system in the washing and selection plant

Coal washing water treatment and recovery system

Solid-liquid separation section in the coal preparation workshop of a coal mine

Environmental protection dust removal

Wastewater treatment

Why wash coal?

1. Improve coal quality and reduce pollution emissions: Coal washing can remove 50% to 80% of ash and 30% to 40%(even 60% to 80%) of inorganic sulfur, reducing the emissions of harmful gases such as so2 and nox.

2. Enhance the utilization efficiency of coal and save energy and reduce consumption: Coal washing can lower the consumption of coke in ironmaking and improve thermal efficiency.

To enhance competitiveness, it is necessary to adjust the structure of coal products, ensure compliance with environmental protection standards, and improve the quality and variety of coal products.

4. Reduce total transportation costs: After washing, some ineffective impurities are removed, reducing the volume of coal products and thus significantly lowering transportation costs.

|

Series |

Model number |

Density

(warp/weft)

(counts/10cm) |

Weight (g/sq.m) |

Bursting strength

(warp/weft)

(N/50mm) |

Air permeability

(L/sqm.S)

@200pa |

Construction (T=twill;

S=satin;

P=plain)

(0=others)

|

|

Coal washing Filter fabric |

CW52 |

600/240 |

300 |

3500/1800 |

650 |

S |

|

Coal washing Filter fabric |

CW54 |

472/224 |

355 |

2400/2100 |

650 |

S |

|

Coal washing Filter fabric |

CW57 |

472/224 |

340 |

2600/2200 |

950 | S |

|

Coal washing Filter fabric |

CW59-66 |

472/212 |

370 |

2600/2500 |

900 | S |

Product advantages

1. High-efficiency filtration and ventilation: It is conducive to rapid dehydration without affecting the filtration quality, especially for the solid-liquid separation of fine-grained coal slime.

2. The filter cake is smooth and flat, and easy to fall off: This helps to reduce the time spent manually brushing the filter element, thereby lowering maintenance costs.

3. Difficult to clog and reusable: Even after cleaning, it remains excellent and has a longer replacement time, thereby reducing the total operating cost.

4. Provide degree design support: It can better match various environments. Different environments require different materials and structures to meet the needs of various coal washing systems.

If you need more technical details, price or customization support for coal washing filter fabric, we strongly recommend that you contact us directly. You will obtain a more applicable solution.