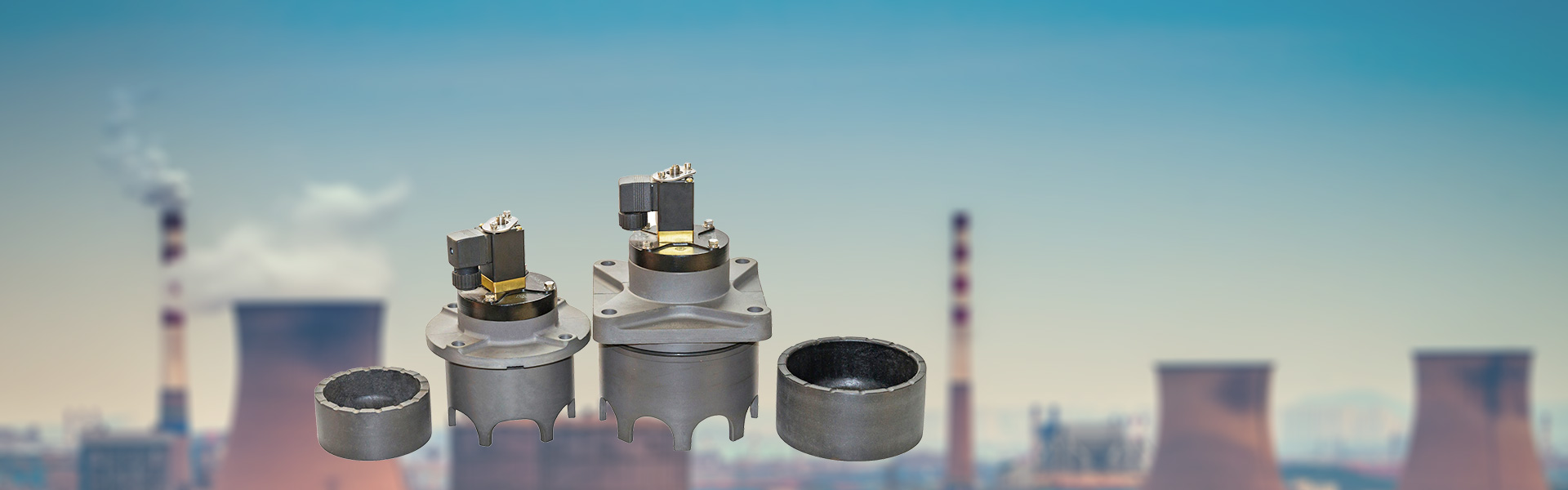

DC24V 3 Inch Dust Collector Valve

Send Inquiry

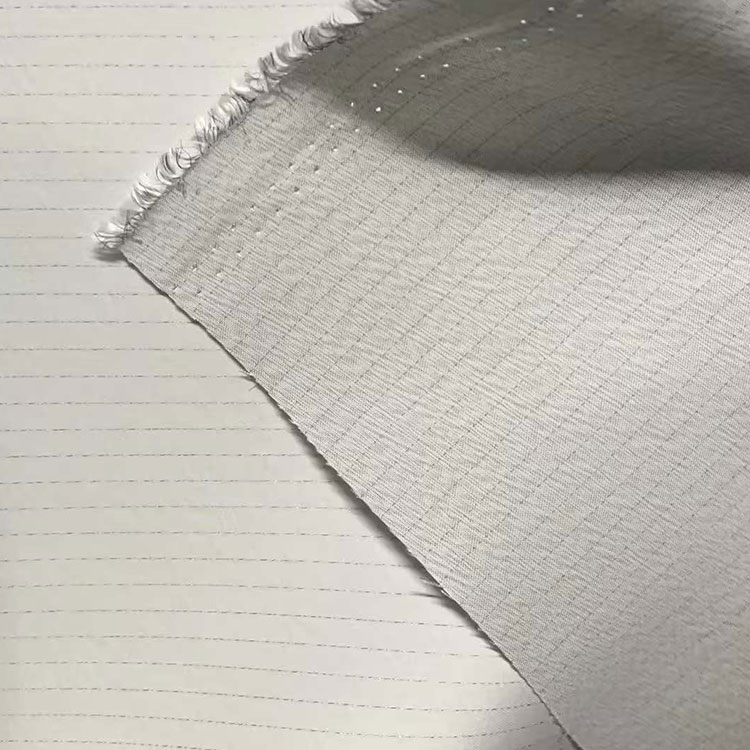

Qingdao Star Machine's DC24V 3 inch Dust Collector Valve is of high quality and the reinforced diaphragm of the valve is made of nitrile butadiene rubber (NBR), a very durable material that ensures a long service life even in challenging environments. aluminium alloy housing, high strength and corrosion resistance.

Product Parameter (Specification)

| Working pressure | 0.2-0.6MPa | Diaphragm life | Over one million cycles |

| relative humidity | <85% | working medium | Clean air |

| voltage, current | DC24V,0.8A;AC220V,0.14A;AC110V,0.3A | ||

Closing the Valve

The solenoid is closed to ambient and opened to the pilot air.

The pilot membrane is pressed down towards the seat.

Via the slot between the plunge and the house the pressure above the plunge will be equalised to the tank pressure and the plunge moves down to the pulse pipe and ends the cleaning pulse.

The time for a sequence (start opening to closed valve) is to some extent depending on process requirements but generally it is in the range of 100– 200 msec.

PILOT AIR CONNECTION

The pilot air for the solenoid is taken from the incoming tube to the pressure tank. The pipe for the pilot air is common for all valves in one tank and is connected upstream the main on- off valve of respective tank.

The pipe should have an on-off valve and a non-return valve which ensures that pressure is kept also if pressure decreases during pulsing.

Note: If a separate feeding pipe for the pilot

air is used the pressure for the pilot air should be approx equal to pressure in tank.

A too high pressure will give a remaining deformation to the membrane, which will reduce the lifetime and have a reducing effect on the function of the pulse cleaning.