Dust Filter Cloth

Send Inquiry

Introducing the Product

The Dust Filter Cloth, a superior material, is tailor-made for filtering industrial dust. This item is crafted using premium synthetic fibers like polypropylene (PP) and polyethylene (PE) via a unique method. This method finds extensive application in bag-style dust elimination devices across sectors like cement, metallurgy, energy, chemical engineering, and waste burning. This device is capable of effectively trapping dust particles as small as microns, guaranteeing adherence to emission norms and prolonging the lifespan of filter bags. This substance serves as a fundamental filter in industrial environmental safeguarding.

Features of the Dust Filter Cloth

Adaptation to various materials

Substances like PP, PE, and PET are chosen based on their operational environments, catering to the filtration needs of varying temperatures (ranging from -40°C to 130°C), acidic and alkaline conditions, and dust properties.

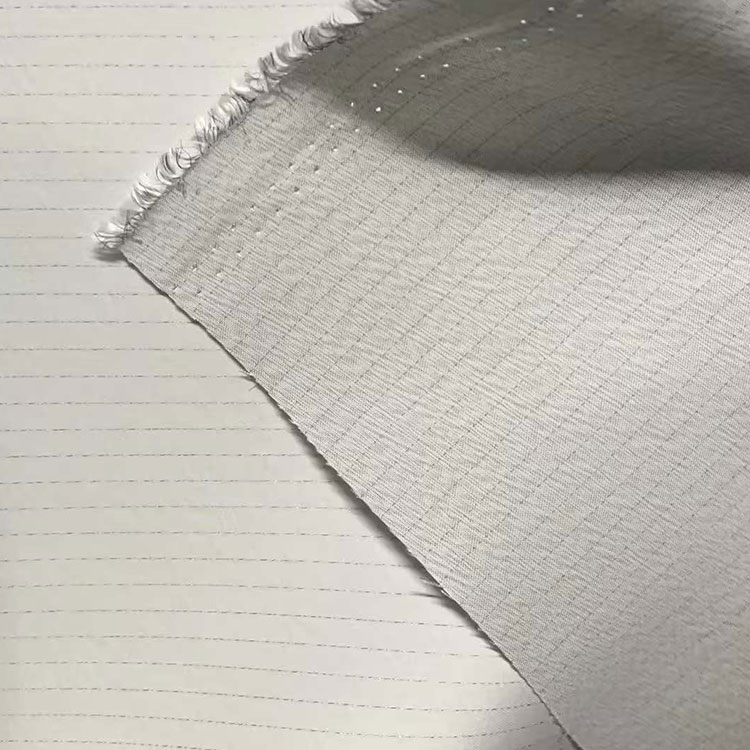

Precise filtering framework

The design utilizes a gradient fiber layer. The outer layer is thick enough to capture sizable particles, whereas the inner layer features gradient pores for effective trapping of fine dust. The efficiency of the filtration process surpasses 99.9%.

Superb longevity

Fiber weaving, known for its robustness and minimal elongation, boasts superior tensile and wear resistance. This item is resistant to the effects of high-frequency pulse ash cleaning and remains intact without deformation or damage, even with prolonged usage.

Cleaning the surface is straightforward

Options for film coating, singeing, or other coating techniques exist to lessen surface stickiness, greatly enhance the effectiveness of ash cleaning, and keep the filtration pressure difference consistent.

Safeguarding the environment and ensuring safety

This substance adheres to RoHS regulations, emits no toxic materials, and can be recycled and regenerated, aiding businesses in reaching their eco-friendly production targets.

Benefits of the Dust Filter Cloth

Tailored assistance

Offers the ability to personalize settings like grammage (100-800g/m2), air permeability, thickness, and width, and works with different dust collectors, including pulse and reverse blowing types.

Economical and outstanding

Its design with a substantial dust retention capacity lessens dust cleaning regularity, prolongs the replacement period, and slashes the overall maintenance expenses by over 30%.

Adjusting to severe work environments

PP filter fabric: Superior resistance to acid and alkali, ideal for use in situations like coal-powered boilers and chemical dust.

PE filter cloth stands out for its robust hydrolysis resistance in environments with high humidity, making it the favored option for burning waste and generating biomass power.

Coated filter cloth: An effective instrument for capturing ultrafine dust particles (PM2.5)

Comprehensive life cycle assistance

Our technical consultancy extends from advising on selection, installation, and commissioning to maintaining and optimizing systems to enhance operational efficiency.

Common areas of application

System for eliminating dust in rotary kilns and coal mills within cement factories

Processing of exhaust gases from boilers in thermal power stations

The process of purifying sintering machines and blast furnace gas within steel manufacturing facilities.

The process of filtering flue gas in power plants that burn waste

The chemical sector's focus on powder recovery and treating volatile organic compounds (VOCs).