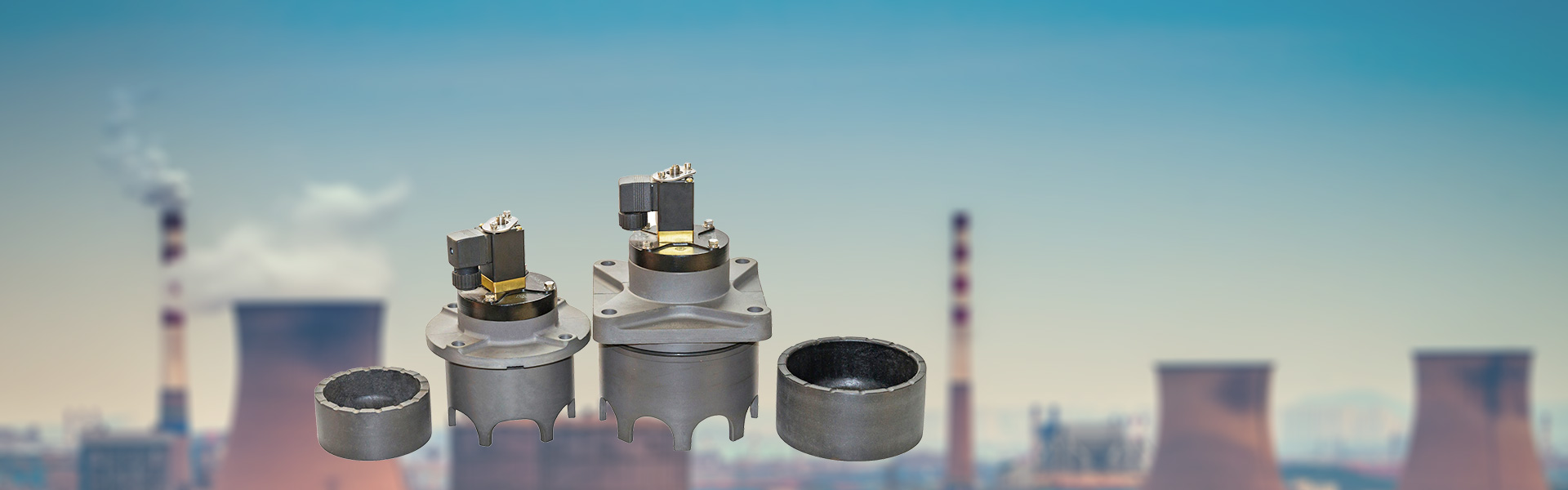

Dust Removal Pulse Solenoid Valve

Send Inquiry

Starmachinechina135 pulse cleaning solenoid valve optimizes system performance in dust removal system applications. Its dynamic response time ≤15ms and operating pressure drop ≤0.03MPa technical indicators achieve a 98% improvement in cleaning efficiency in the bag filter pulse cleaning system. The valve body has passed shock test, and the core component MTBF (mean time between failures) exceeds 60,000 hours, meeting the continuous operation requirements of high dust concentration scenes such as metallurgy and cement.

PILOT AIR CONNECTION

Dust removal pulse solenoid valve has pilot solenoid. The solenoid's pilot air is sourced from the incoming tube connected to the pressure tank. A single pipe is designated for pilot air distribution, servicing all valves within a given tank. This pipe is linked upstream to the main on-off valve specific to each tank.

To maintain pressure even during pulsing, this pilot air pipe necessitates the inclusion of an on-off valve and a non-return valve. It's imperative to note that if an independent supply pipe is employed for the pilot air, its pressure should be approximately equal to that in the tank.

Caution should be exercised to avoid excessive pressure, as it could result in undesired membrane deformation, ultimately diminishing the lifespan and compromising the effectiveness of the pulse cleaning function. Illegal operation may affect the life of your Dust removal pulse solenoid valve.

product drawing