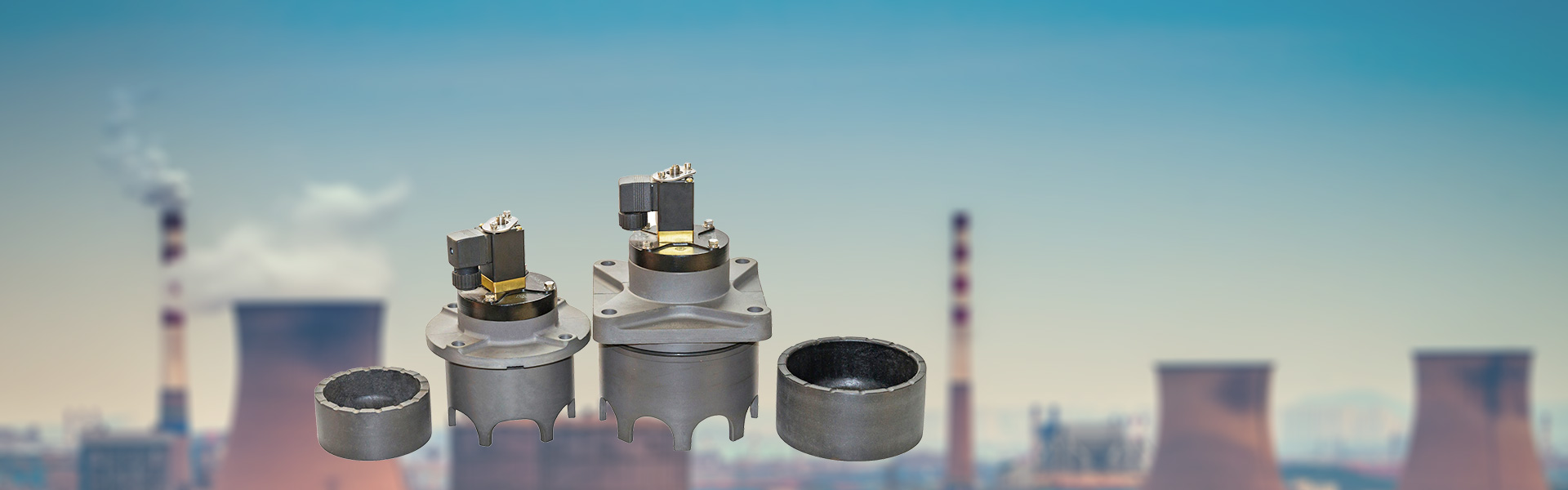

Dust Removal Solenoid Valve

Send Inquiry

Dust Removal Solenoid Valve of Qingdao Star Machine is high quality and reasonable price.

Under normal operating conditions, the solenoid valve is in the locking mode, and the multi-layer composite diaphragm assembly applies pre-tightening force to make the piston sealing end face fit tightly with the valve seat, effectively blocking the connection between the air inlet chamber (P port) and the air outlet chamber (A port). In this state, the system pressure difference is stably maintained within the set threshold to ensure the isolation of the dust collector gas path.

When the control system sends a pulse command, the excitation circuit of the electromagnetic drive unit is turned on, generating an electromagnetic suction force of ≥23N, driving the piston assembly to complete a 12mm stroke displacement within 8ms. At this time, the P-A flow channel is turned on, and the compressed air forms a high-speed jet under the action of a pressure difference of 0.5-0.7MPa, and the dust on the surface of the filter bag is stripped through the Venturi effect, and the dust cleaning efficiency is ≥98.5%.

After the pulse cycle ends, the electromagnetic unit is demagnetized, and the piston is reset under the action of the elastic restoring force of the diaphragm. The reset process takes ≤10ms, ensuring that the P-A channel is restored to a completely sealed state, and the system back pressure loss rate is ≤0.3%. The fast opening and closing feature enables the valve to perform 30 cleaning cycles per minute, adapting to high-frequency dust removal conditions.

Product Parameter (Specification)

Features of Dust Removal Solenoid Valve include:

1 Under the condition of meeting the pressure difference, can be installed arbitrarily (customized).

2 can also work under zero pressure difference, vacuum and high pressure, but the power is large, must be installed horizontally.

In addition, the dust removal solenoid valve has other advantages, such as wide versatility, high sensitivity, strong sealing, long life and so on.