PE Filter Cloth

Send Inquiry

Product Description

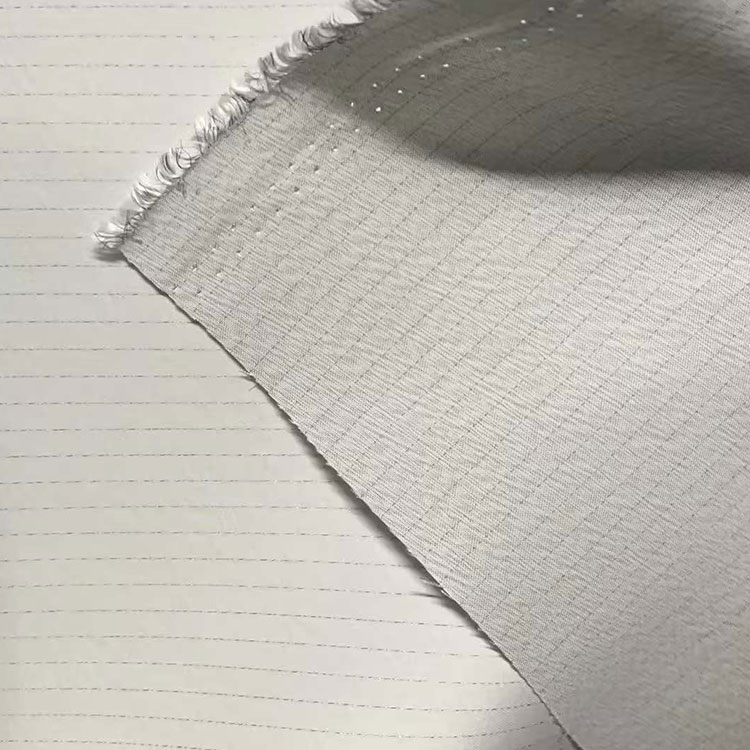

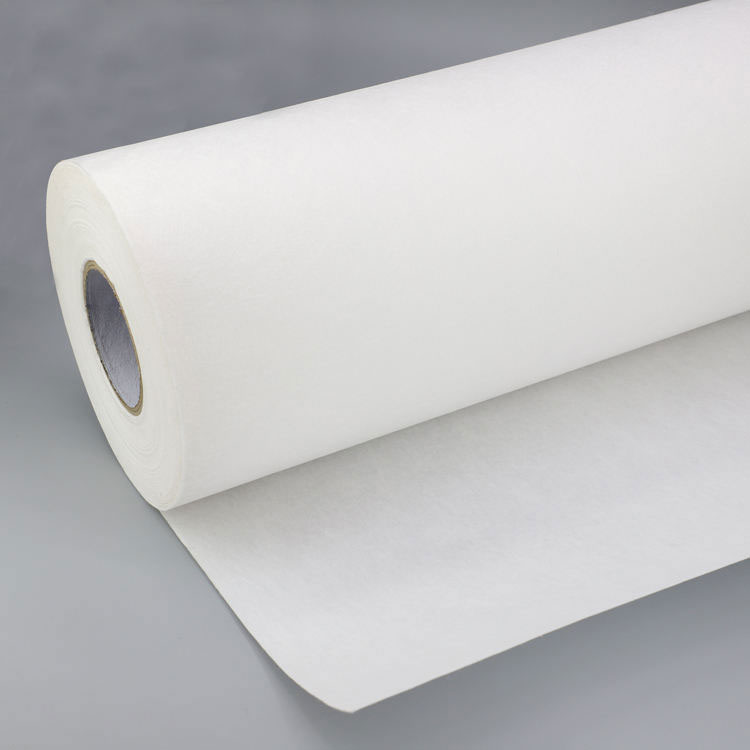

PE Filter Cloth is based on high-quality polyester materials and is specially designed for industrial filtration needs. It can not only meet the general industrial demands for high-strength and high-wear-resistant filter materials, but also adapt to the usage requirements under high-temperature conditions. This product features outstanding acid and alkali resistance, excellent wear resistance and corrosion resistance, and can operate stably at a maximum temperature of 120°C. Meanwhile,PE Filter Cloth also features excellent anti-static properties, high-temperature resistance, and resistance to both high and low temperatures, which can meet the requirements of various industries for filter cloth. Based on the structural differences of the fibers, we can classify the products into two major types: polyester long-fiber filter cloth and polyester short-fiber filter cloth. They can adapt to various working environments.

Advantage

PE Filter Cloth features extremely high strength and durability, with a breaking strength as high as 438g/d. This endows it with strong tensile and tear resistance, allowing it to be used for a long time in high-pressure and high-wear environments.

Capable of withstanding high temperatures and pressures: Its applicable temperature range is from -70°C to 150°C, and its pressure resistance can reach up to 10MPa, making it highly suitable for use in various extreme working environments.

Outstanding air permeability and filtration capacity: Its unique weaving method ensures excellent air circulation, thereby achieving rapid dehydration and efficient dust removal effects.

Outstanding chemical corrosion resistance: It can resist the erosion of acidic and weakly alkaline substances for a long time, thereby extending the service life of the filter cloth.

To facilitate cleaning and maintenance, the PE Filter Cloth has undergone a smooth surface treatment and a low shrinkage rate design. This makes the filter cloth less prone to clogging and also easy to blow back and clean, thereby effectively reducing the machine's downtime.

Product Parameter (Specification)

| Weaving | WEIGHT | Density (PC/10CM) | THICKNESS | Breaking Strength (N/5*20CM) | Elongation At Break (%) | Air Permeability | |||

| G/㎡ | weft | warp | MM | weft | warp | weft | warp | (L/㎡.S) | |

| Polyester Long Fiber | 340 | 192 | 130 | 0. 65 | 4380 | 3575 | 50 | 30 | 55 |

| Polyester Long Fiber | 440 | 260 | 145 | 0.78 | 4380 | 3575 | 50 | 30 | 60 |

| Polyester Staple Fiber | 248 | 226 | 158 | 0. 75 | 2244 | 1371 | 31 | 15 | 120 |

| Polyester Staple Fiber | 330 | 194 | 134 | 0.73 | 2721 | 2408 | 44.2 | 21.3 | 100 |

| Polyester Staple Fiber | 524 | 156 | 106 | 0. 90 | 3227 | 2544 | 60 | 23 | 25 |

| Polyester Needle Punched | 1.80 | 18 | |||||||

Production Process

Qingdao Star Machine Co., Ltd. has always adhered to the business philosophy of "Quality First, Customer Foremost", and is committed to providing customers with stable and efficient filtration solutions. Among the numerous filtration equipment manufacturers, how did we manage to achieve this? If you would like to obtain more information, please feel free to contact our team of industry experts at any time. We promise to supply the most suitable products for your filtration systems.